These are boiler plates that can withstand high pressure and temperatures. Their quality, requirements for processing and properties are governed by regulation EN 10028-2. They are characterized by good weldability and corrosion resistance. You will use them not only in the chemical, food, pharmaceutical, but also in the energy industry.

Properties and use of ordinary steel boiler plates according to EN 10028-2

Boiler plates made of unalloyed and alloyed stainless steel stand out for their excellent resistance to high pressure, temperature and corrosion. They are characterized by excellent weldability and good resistance to hydrogen embrittlement. Boiler plates made of ordinary steel, the technical requirements of which are specified by regulation EN 10028-2, are usually delivered in the normalized annealed state, or in the normalized annealed and tempered state.

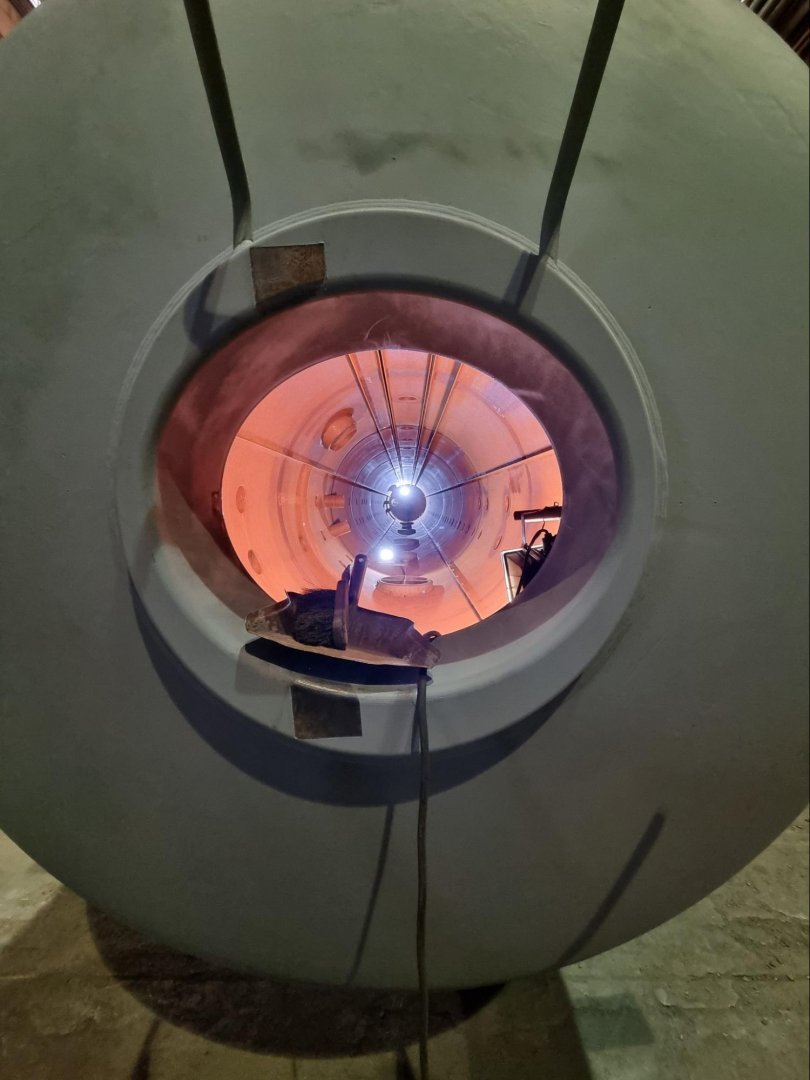

Their properties guarantee use in various applications permanently exposed to high temperatures. Suitable for pressure vessels and equipment. You use them on steam boilers, heat exchangers, gas storage tanks and transport containers. They are also suitable for the production of structural elements and components in engineering that are exposed to high pressure or temperature. Boiler plates can be used in the chemical, food, pharmaceutical and petrochemical industries or in the field of energy, waste management or the environment.

Choose from a wide range of sizes.

We supply sheets in the following dimensions:

- length: max. 18,000 mm,

- width: 1000-3200mm,

- thickness: 5-100 mm,

- weight: max. 12,500 kg.

The stated dimensions are only approximate. The resulting appearance depends on the combination of individual parameters and material specification. Upon agreement, we are able to produce sheets up to a length of 21,000 mm and a thickness of 200 mm.

For more information

Equivalent marking of steels

| EN 10028-2 | DIN 17155 |

|---|---|

| Quality P235 | GH H I |

| Quality P265 | GH H II |

| Quality P295 | GH 17Mn4 |

| Quality P355 | GH 19Mn6 |

| Quality 16Mo3 | 15Mo3 |

| Quality 13CrMo4-5 | 13CrMo44 |

Basic characteristics of individual qualities

| Steel brand | Minimum yield strength ReH1) [MPa] |

Minimum yield strength 0.2% Rp022) [MPa] |

Strength limit Rm [MPa] |

Minimum ductility [%] |

Minimum impact work KV [°C/J] |

Thickness4) [mm] |

|---|---|---|---|---|---|---|

| P235GH/1.03453+5) | 235 | 153 | 360-480 | 24 | −20/27 | 5-80 |

| P265GH/1.04253+5) | 265 | 173 | 410-530 | 22 | −20/27 | 5-80 |

| P295GH/1.04813+5) | 295 | 192 | 460-580 | 21 | −20/27 | 5-80 |

| P355GH/1.04733+5) | 355 | 232 | 510-650 | 20 | −20/27 | 5-80 |

| 16Mo3/1.54155) | 275 | 194 | 440-590 | 22 | +20/31 | 6-80 |

| 13CrMo4-5/.73355) | 300 | 216 | 450-600 | 19 | +20/31 | 6-80 |

- Valid for thicknesses up to 16 mm, larger thicknesses according to the standard

- Testing by agreement, values apply to a temperature of 300 °C and a thickness of up to 16 mm, other temperatures or greater thickness according to the standard

- Maximum carbon equivalent value according to the relationship

by agreement

- Greater thickness up to 100 mm by agreement

- By agreement according to EU PED 2014/68/EU and AD 2000 – Merkblatt W1/W10